This UK startup is using recycled plastic to build better, cheaper, and longer lasting roads (A spotlight on sustainable startup)

Do you know that more than 8 million tons of plastic are dumped in our oceans every year? According to PlasticOceans.org, we now producing nearly 300 million tons of plastic every year. That means about 3% of all the plastics produced end up in the ocean. What about if there is a way to reduce environmental waste, reuse our scarce resources and still make money doing it? This is one of the biggest economic and business challenges we face today. How do we implement business solutions that address resource scarcity, climate change, environmental issues and still make a positive impacts in the world? The is exactly what this UK startup is doing — solving three world challenges that most major corporations have not been able to address. MacRebur is one of the world’s most innovative and sustainable startups you probably never heard of.

This UK-based startup is currently using up millions of tons of waste plastic that sit in our landfill sites, reduce the millions spent on new roads, maintenance, and pothole repair, and making our roads stronger and longer lasting. There are 40 million miles of roads in the world. These roads are made using hundreds of millions of barrels of oil.

Normally roads comprise around 90% rocks, limestone, sand etc., and up to 10% bitumen to bind it. But bitumen is extracted from crude oil, it makes the cost of the road very expensive, and the resource is not renewable. With MacRebur’s method, the secret lies in the mixture of plastic pellets. The plastic pellets or lumps replace a significant part of the bitumen. The plastic lumps are made from plastic waste collected from houses and workplaces which are later processed into plastic lumps. The plastics are then added to the asphalt plant, with some stones from the stone. Toby said the exact content of the blend is a trade secret. After 18 months of testing and trials, Toby’s factory had product ‘MR6’ – waste plastic pellets to replace the non-renewable material bitumen. McCartney’s first tested the mixed plastic asphalt on his driveway. He later tested in Cumbria, North-West of England. McCartney says plastic roads are much cheaper and more durable than asphalt roads.

Toby McCartney tested his plastic-mixed asphalt on his own driveway

MacRebur idea was born when British engineer Toby McCartney, also the founder and CEO, was working in Southern India with a charity helping people who work on landfill sites as “pickers.” Their job was to gather potentially reusable items and sell them on to be turned from rubbish into something useful again. Some of the waste plastics retrieved by the pickers were put into potholes, petrol poured all over them, and the rubbish set alight until the plastics melted into the craters to form a makeshift plastic pothole filler.

When Toby returned back to the UK, Toby thought that his councils might frown upon idea in the UK. So, he got together with two friends, Nick and Gordon, and founded MacRebur. They came up with innovative idea to take a mix of waste plastics, pelletize them and add them into the making of an enhanced asphalt road. After 18 months of testing and trials, we had our product ‘MR6’: It is within British and European standards and is a patent pending, high performance, asphalt binder additive that enhances the roads we drive on today.

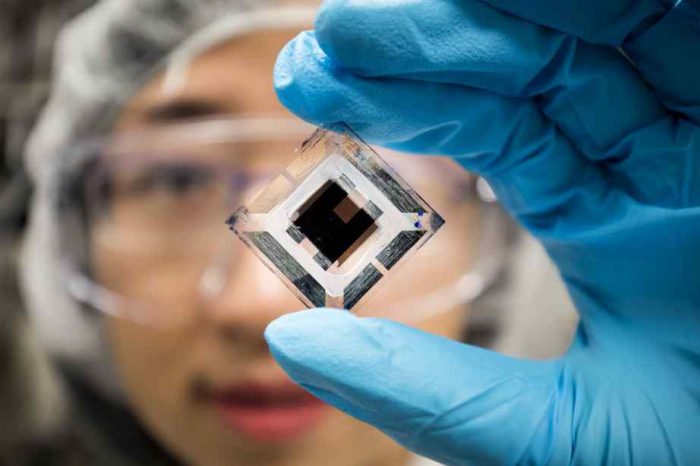

Bitumen Pellet next to British Pence

MacRebur’s products are made from 100% waste materials and are used to replace part of the bitumen in any asphalt mix. Between 3kg to 10kg of waste plastics are used in every ton of asphalt depending on the road design. As fossil fuels are constantly being consumed, alternatives to bitumen must be considered to improve sustainability. The pellets replace part of the bitumen in asphalt, giving a significant reduction in fossil fuel usage. We are seeing the negative effects of a plastic epidemic throughout the world. Since all MacRebur’s MR products are all made from 100% recycled plastic materials, they help reduce unwanted, discarded plastics from landfill and from oceans.

MacRebur’s waste plastic pellets are fully melted into the bitumen within the asphalt mix and so no microbeads are present in the mix – in fact, with MacRebur’s MR products included, less bitumen leaches into rivers and streams.

MacRebur have found an innovative way of using waste plastics to give a cost effective, enhanced asphalt solution. They currently sell their pellets in the UK asphalt market, which produces over 20 million tons per year with four companies dominating. MacRebur already has agreements in place with some of these firms.

Meanwhile, global asphalt production is approximately 1.6 trillion tons per year. They already set their sights on the worldwide market and have already had global interest. They also have strategic alliances in place around the world. MacRebur’s has created a business model that allows them to scale up and roll out our innovative solution on all roads networks, airport runways, racetracks, etc worldwide. Looking to the future, they also believe there are many other areas of construction that could incorporate our MR6 pellets.

In 2016, the company entered the Virgin Media Business Voom competition, up against 9000 businesses looking for support for their new or growing enterprises. After coming 6th place with 2,829 public votes MacRebur went through to the pitchathon round against 160 other companies, a series of competitive workshops and then became one of three finalist to present to Richard Branson on the 28th June and won! This success brought the company from a concept to a fully fledged business, raising our profile to enable us to propel MacRebur® to the next stage of its journey.

Virgin CEO, Richard Branson, with Toby McCartney, the co-founder of MacRebur.

Below is a BBC video with overview of MacRebur and how the company is saving the world.