3D-printing tech startup Azul3D secures $12.5 million in seed funding to support the launch of high-throughput 3D printers

Azul 3D, a Skokie Illinois-based 3D printing tech startup company that allows users to print 3D structures from a wide pallet of materials, today announced it has secured $12.5 million to advance its proprietary high-area rapid printing (HARPTM) technology and launch its first commercial printers.

The oversubscribed seed financing was backed by several new key backers to its growing investor pool, including Louis A. Simpson, former CIO for Geico, Wally Loewenbaum, former chairperson of 3D Systems, Joe Allison, former CEO of Stratasys Direct Manufacturing, Hugh Evans, former senior vice president of corporate development for 3D Systems.

Azul 3D aims to revolutionize advanced manufacturing with high-throughput 3D printing technologies that take ideas from prototyping to manufacturing in a streamlined, low-cost solution. With High-Area Rapid Printing (HARP) technology, Azul 3D can print large objects at unparalleled speeds from a wide range of consumer and industrial-grade plastics. Azul 3D aims to provide an industry-ready solution that enables the production of consumer goods ready to go directly from the printer to the shelf.

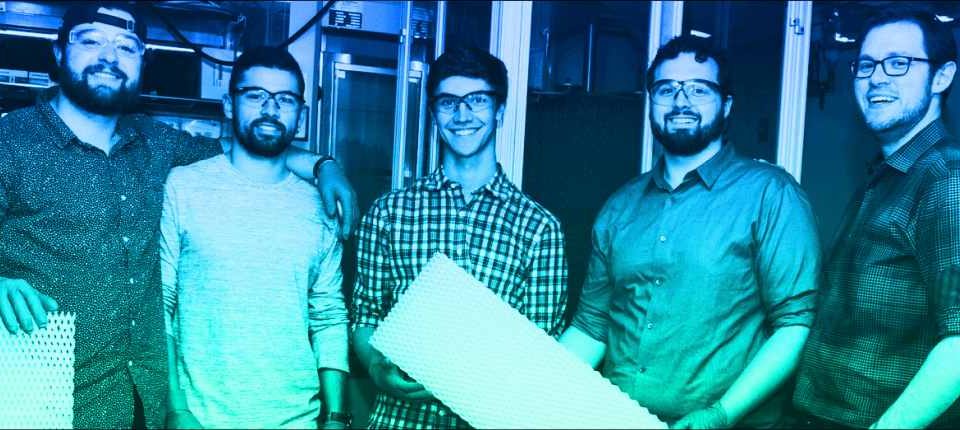

Azul 3D was founded in 2016 by co-founder Chad Mirkin and David Walker. But the original idea behind Azul 3D started way back at Northwestern University where high-area rapid printing (HARPTM) technology was originally invented. The HARPTM technology allows one to print 3D structures from a wide pallet of materials. The initial printers based upon HARPTM are capable of manufacturing parts at production speeds, regardless of size, with a throughput dramatically outpacing its competitors and becoming competitive with injection molding.

The startup is enabling manufacturers to transition from prototype to mass-manufacturing on a single, streamlined production platform. In combination with its proprietary industrial-grade materials, it offers the opportunity for just-in-time mass production of diverse, highly customized products.

“Investors recognize the paradigm-shifting and disruptive nature of Azul’s proprietary HARP 3D printing technology,” said Chad Mirkin, Azul 3D co-founder, and chair.

HARP’s throughput allows Azul to substantially lower the upfront and sustained costs in the manufacturing of goods, spanning many sectors. “The company intends to secure major partnerships validating this point in the very near future,” Mirkin said.

During the COVID-19 pandemic, one of the company’s subsidiaries demonstrated such capabilities using its instrumentation to print personal protective equipment (PPE) for hospitals, prisons, first responders, and members of the Navajo Nation.

“One of the reasons we’re doing so well is because our technology offers a solution to unexpected surges in demand and supply-chain bottlenecks that occur during global crises, such as in the current pandemic,” said David Walker, Azul 3D co-founder, and chief technology officer. “With the ability to manufacture nearly anything quickly and on-demand, we can meet these unexpected needs as they arise to quickly fill gaps in the supply chain. That’s the big difference between HARP and traditional manufacturing as well as many other forms of 3D printing, which either don’t have the throughput or material properties to meet the required specifications. We don’t have to change a whole assembly line or machine new molds. The concerns that accompany a stressed supply chain simply vanish.”

Using HARP, the Azul 3D team is now producing medical face shields at a record rate of 1,000 components per printer in a 12-hour shift.