NextFlex secures seven years of funding, up to $154M, from Air Force Research Laboratory and OSD to fuel electronics innovation for manufacturing and military purposes

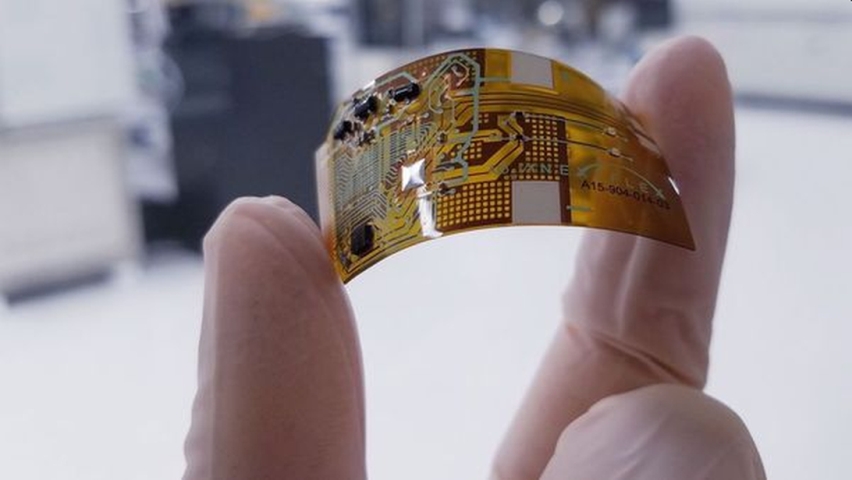

Early this year, we wrote about NextFlex, after the consortium announced $12M in funding to promote the adoption of Flexible Hybrid Electronics and development in the US advanced manufacturing industry. NextFlex is a consortium of companies, academic institutions, non-profits and state, local and federal government partners with the shared goal of advancing the manufacture of flexible hybrid electronics in the U.S., in collaboration with America’s Flexible Hybrid Electronics (FHE) Manufacturing Institute

Today, NextFlex, America’s Flexible Hybrid Electronics (FHE) Manufacturing Innovation Institute, announced today that it has secured seven years of government funding worth up to $154M in a cost-sharing agreement with the Air Force Research Laboratory (AFRL). The seven-year agreement also includes funding from the Office of the Secretary of Defense’s (OSD) Manufacturing Technology program, which focuses on cross-cutting defense manufacturing needs.

Founded in 2015, NextFlex is a consortium of companies, academic institutions, non-profits and state, local and federal government partners with the shared goal of advancing the manufacture of flexible hybrid electronics in the U.S. Since inception, the NextFlex community of technologists, educators, problem solvers and manufacturers have come together to collectively facilitate innovation, narrow the manufacturing workforce gap and promote sustainable manufacturing ecosystems.

The funds will be used to directly support NextFlex’s ongoing mission to drive manufacturing technology needs for OSD Research & Engineering modernization priorities and developing FHE innovations to accelerate its adoption in the US, with particular focus given to Department of Defense technology transitions that increase military capabilities, and on developing a robust FHE workforce.

“We’re beginning to see some of the initial projects we’ve collaborated on with our members make great strides towards the market, or towards active military use,” explains NextFlex Executive Director Dr. Malcolm Thompson. “As the leading member organization and collaboration partner in the field of FHE, we know this new funding will pave the way towards the vision of Electronics Everywhere.”

Under the new Cooperative Agreement, NextFlex will update and extend its project support and technology roadmaps into FHE manufacturing in partnership with DoD and other government agencies to achieve specific goals in support of these agencies’ missions. With the additional funding, the Institute will also be able to expand on the number of FHE projects with its member partners and continue building a more robust FHE ecosystem in the US.

“We are excited to continue our partnership with NextFlex and its members. The Flexible Hybrid Electronic manufacturing ecosystem did not exist five years ago,” said Dr. Richard Vaia, Chief Scientist for the Materials and Manufacturing Directorate at AFRL. “Today these technologies are not only providing component solutions to our current platforms but are revolutionizing our design concepts for future transformation capabilities for 2030.“

“Over the last five years, the DoD and Government partnership with NextFlex and members demonstrated numerous flexible hybrid electronics-based prototypes for Modernization Priorities. We are excited to support the OSD ManTech Office in the execution of the second AFRL Cooperative Agreement. Many new approaches will be implemented in the second agreement supporting emerging National Advanced Manufacturing challenges and DoD priorities,” said Dr. Eric Forsythe, NextFlex Government Program Manager and ERP SAMM Hybrid Thrust Lead at the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory.

NextFlex also announced today that it has received an additional $10M through the Department of Defense (DOD) Defense-wide Manufacturing Science and Technology Program to advance the state of the art for defense-essential manufacturing capability, through the development of technologies and processes necessary for the production of defense systems. This funding will be used for projects within NextFlex’s 100-member network that advance FHE manufacturing processes in support of DOD advanced manufacturing goals.

“I am proud to support Nextflex’s successful collaborations with organizations like The Center for Advanced Microelectronics Manufacturing (CAMM) at Binghamton University,” said Rep. Anthony Brindisi (NY-22). “I applaud NextFlex’s decision to use additional federal funding for advanced manufacturing projects that will accelerate the adoption of flexible hybrid electronics in the US.”