NextFlex announces $12M in funding to promote the adoption of Flexible Hybrid Electronics and development in the US advanced manufacturing industry

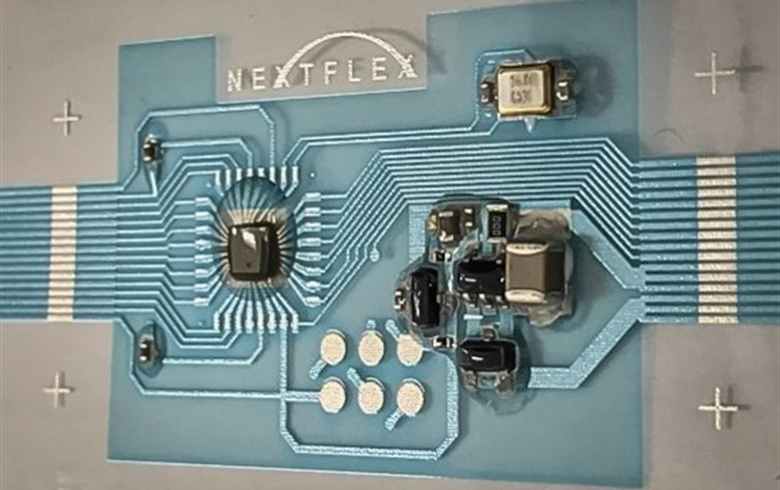

NextFlex, a consortium of companies, academic institutions, non-profits and state, local and federal government partners with the shared goal of advancing the manufacture of flexible hybrid electronics in the U.S., in collaboration with America’s Flexible Hybrid Electronics (FHE) Manufacturing Institute, today announced $12 million in funding for seven projects as part of its Project Call 4.0 initiative.

The funding, which includes $7M in cost-share contribution from participants, will be used to further promote FHE adoption and development in the US advanced manufacturing industry. This latest round of funding brings the total amount invested in FHE developments to $88.6M, including cost share.

NextFlex was formed in 2015 through a cooperative agreement between the US Department of Defense (DoD) and FlexTech Alliance, NextFlex is a consortium of companies, academic institutions, non-profits and state, local and federal governments with a shared goal of advancing U.S.

Project Call 4.0’s project winners are diverse and innovative, tackling scopes that address the industry’s key challenges, directly demonstrate manufacturing capabilities and offer a forward-thinking plan for transitioning projects to U.S. industrial manufacturing. The array of projects includes a wearable patch to monitor interstitial fluid biomarkers for disease and fatigue, encapsulation solutions to protect wearable electronics from environmental factors, systems to enhance capability of small unmanned aerial vehicles (UAVs), and all projects utilize and promote FHE technology.

“We’re delighted to announce the Project Call 4.0 awards. These projects will drive FHE manufacturing processes to a new level of sophistication,” said Malcolm Thompson, Executive Director at NextFlex. “Each successive Project Call builds upon developments and learning from previous ones, staying focused on member-identified manufacturing challenges and creating optimal opportunities for collaboration.”

Previous Project Calls received over 178 proposals with a total of $75 million in investment towards promoting FHE breakthroughs. Projects chosen for Project Call 4.0 are a continuation of the previous success and developments stemming from the entire Project Call FHE Roadmap series.

The seven projects awarded funding are:

- Development led by Flex on encapsulation solutions for wearable electronics

- Development led by Lockheed Martin and Binghamton University of FHE systems to reduce weight, enhance performance, and improve communications capability of small fixed-wing unmanned aircraft systems (UAVs)

- Development led by The Boeing Company of FHE skins to improve performance and add functionality to small multi-rotor UAVs

- Development led by Eastman Chemical and UMass Lowell of processes and demonstrations for FHE device encapsulation

- Development led by The Boeing Company on using additive printing to manufacture multi-layer flexible circuit boards with integrated electronics

- Development led by GE Global Research and Binghamton University of a fully integrated and minimally invasive wearable device for on-demand monitoring of metabolites and cytokines from interstitial fluid

- Development led by The Boeing Company of a smart textile with embedded and printed sensors for structural health monitoring

Founded in 2015, NextFlex is a consortium of companies, academic institutions, non-profits and state, local and federal government partners with the shared goal of advancing the manufacture of flexible hybrid electronics in the U.S. Since inception, the NextFlex community of technologists, educators, problem solvers and manufacturers have come together to collectively facilitate innovation, narrow the manufacturing workforce gap and promote sustainable manufacturing ecosystems.