This Ukrainian startup will build you an off-the-grid 3D-printed house in as little as eight hours

Have you ever dreamed of living in an off-the-grid house where you don’t have to worry about the hustle and bustle of big cities? PassivDom may be able to help you make your dream come true. PassivDom is an Ukrainian startup and the maker of an autonomous off-the-grid 3D-printed house. The startup is about to disrupt the entire tiny house market by creating mobile homes that can be made anywhere and are completely self-powered. For as little as $64,000, PassivDom 3D printing robot will print the walls, roof, and floor of 410-square-foot model in about eight hours. The windows, doors, plumbing, and electrical systems are then added by a human worker. The company was started in March 2016 by Julia Gerbut and Max Gerbut. So far, the company has received over 8,000 pre-orders in the United States for its homes. The first hundred homes will be delivered in January 2018.

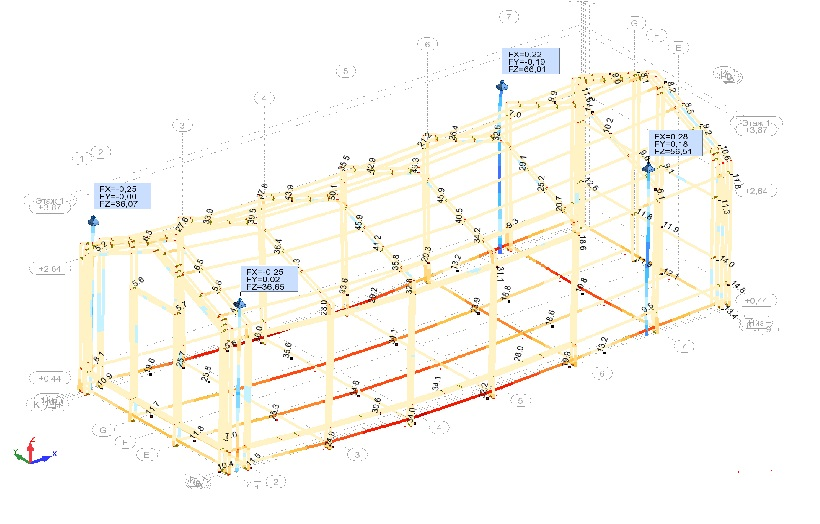

PassivDom’s smallest model measures 410 square feet and ranges from $64,000 to $97,000, designer Maria Sorokina told Business Insider. The 775-square-foot model ranges from $97,000 to $147,000. PassivDom can also make custom models as well. The premium models come with furniture, a kitchen, a bathroom, engineering systems, an energy supply, a water tank, and a sewage system. To make a home, PassivDom team maps out the plan for the 3D printer in its factories in Ukraine and California. Then, layer by layer, the seven-axel robot prints the roof, floor, and 20-centimeter-thick walls, which are made of carbon fibers, polyurethane, resins, basalt fibers, and fiberglass.

PassivDom combines several innovative features:

- 1. Energy efficient technology for autonomous off-grid buildings;

- 2. Zero Carbon emission, solar energy only;

- 3. 3D-printed prefabricated frame, using carbon fiber, fiberglass, nano basalt fiber, and polyurethane;

- 4. Self-learning smart house operating system with integrated IoT network;

- 5. Mobile modular solution, no foundation needed.

“The house frame is printed as a single component which is manufactured in a mechanized way. The frame is printed with the use of industrial 7-axes robots. The house frame consists of walls, floor basement, and roof. So we print whole house base in one cycle. It is the one difference between our technology and others 3D-printing construction companies: robots print not only walls but the whole house,” PassivDom’s PR Manager, Maria Sorokina said.

“We use carbon fiber, polyurethane, basalt, resins, and fiberglass for printing. In the first step, robots mix components in composite with high thermal and resistant characteristics. That is how we get extremely durable construction along with maximum warmth. A composite is extruding layer by layer as in a ‘usual’ 3D-printing.”