Vaquform: Go beyond the conventional vacuum former

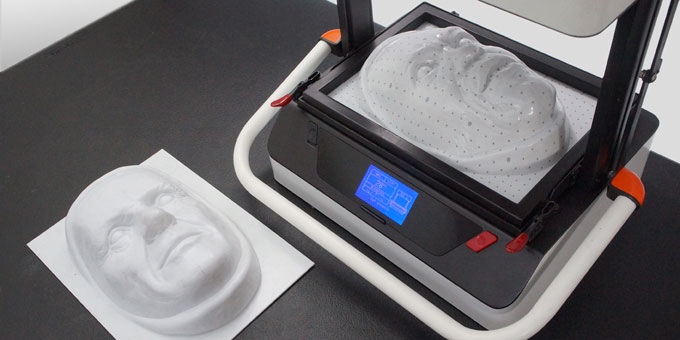

Either you’re a project maker or a passionate hobbyist who wants to tinker around modeling stuff, you can benefit from a vacuum former that carries industrial-quality features and smart technologies combined with desktop-friendly portability. Introducing the Vaquform, a smart vacuum forming machine that enables more creators to improve and refine their craft without the bulk and high cost of conventional vacuum forming sets. It’s a prototyping machine built for the modern maker where portability and smart features do matter the most. Read on to know more about this compact yet fully-featured creation tool.

Vaquform sets itself apart from conventional vacuum forming machines, as it integrates modern digital controls for both the user interface and process control. Going far beyond what a normal vacuum former can do, Vaquform stands out as a smart appliance with its sophisticated process controls and a user interface that takes the complexity out of the task. And thanks to its well-thought compact form factor, it rivals the performance of industrial vacuum formers that cost thousands of dollars more – without the prohibitive price tag, making it an attractive option for small craft makers and startups who want to streamline their manufacturing process while preserving capital.

From a technological perspective, Vaquform offers an unprecedented amount of features for its small size. It’s rated to be up to four times as strong as a vacuum cleaner, translating into a better vacuum forming process through improved air removal. Vaquform makes the vacuum forming process easier and more precise thanks to its two-stage hybrid system. This system employs a high-speed impeller in the first stage that removes up to 90% of air under the forming plastic sheet, then a second-stage high-performance vacuum squeezes the remaining pockets of air and shapes the material sheet into the mold with extreme precision. The result is a tightly formed shell, revealing detailed curves and corners that you wouldn’t expect from a desktop vacuum machine.

A digital user interface takes care of the Vaquform’s smooth operation. Temperature profiles built within the system are matched with the exact kind of material you put in, so there are no calibrations or unnecessary adjustments needed for the right forming temperature setting – Vaquform knows what you put in, and what results you should expect. From the LCD menu, it takes to press the start button to let Vaquform do the rest. With a great flexibility to use almost anything as a mold, there are no limits to what you can do with it.

If you’re in the market for a well-equipped vacuum forming device, the Vaquform can easily qualify for the things you’re looking for in such a machine. Its combination of smart vacuum forming technologies, straightforward operation, and wide material flexibility makes up for a manufacturing innovation suited for the modern age.