LokBuild: Build your 3D-printed projects with ease

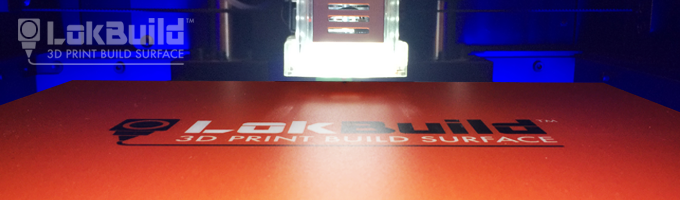

If you have been making 3D-printed crafts for some time, you’ve come to realize that your printed objects usually stick to some surfaces. And that’s a real problem. Even with many printing surfaces available, warping and sticking problems still exist. LokBuild is trying to change that with a durable and stable printing surface, which promises to make warping and sticking just things of the past.

Specifically made for fused filament fabrication (FFF) and fused deposition modeling (FDM) 3D printers, LokBuild builds on the idea of preventing model warping while providing a grippy and stable 3D surface to work with. If you have messed around with makeshift solutions like tapes, sprays, and slurries, this printing surface could end your struggles.

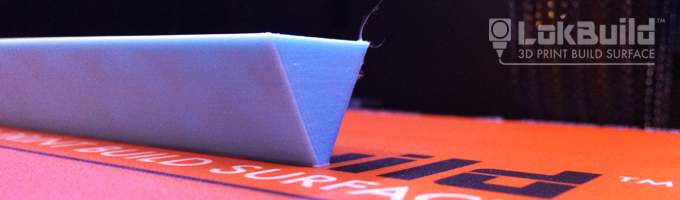

LokBuild works in two ways: first, it acts as a grippy printing surface where you can stick your printed models securely, and second, it also allows completed objects to be removed easily. It sticks to the bed of your 3D printer, so it directly preps up your model builds while it’s being made. With two different sizes, it’s made to fit any 3D printer out there. If your printer has a different configuration, you can also cut out or combine multiple pads to match your desired build surface. A heat-resistant adhesive backing makes it stable enough to withstand your 3D printer’s build plate while in operation.

LokBuild makes a sturdy yet clean bond between your printed models and the build surface. When you’re done printing, your builds will be easy to remove without the need for scraping and forceful removal. Another common problem with some 3D printing surfaces is the accuracy needed when setting the printer nozzle height from the bed. When it’s set too far, the print will warp. Too close and the print will be damaged due to forceful removal. LokBuild is forgiving in nozzle calibration, so it’s easy to set your printing surface without so much effort.

It’s also made to withstand multiple printing sessions as it is heat resistant. You can use LokBuild hundreds of times before replacing it, thanks to its durable surface finish. You can also use it with many different types of filament without needing to change the printing surface.

LokBuild works for both ABS plastic and polyactide (PLA) plastic allowing you to switch between materials without the need to change the build surface between prints. In addition, it also works with other rare 3D printing materials including HIPS, PET, ColorFabb XT, ColorFabb XT-Carbon Fibre, Woodfill, Bronzefill, Copperfill, Brassfill, some polycarbonate materials, and flexible materials such as PolyFlex and Ninjaflex.

3D printing would be more enjoyable to do without issues like failing surface alternatives, warping, and print sticking. LokBuild helps you to achieve a more sturdy 3D printing process, with a durable printing surface you can use over and over for many kinds of prints.