This startup is helping waste pickers make money by recycling plastic waste into 3-D printer filament

Around the world and most especially in developing countries, there are millions of people who collect reusable or recyclable materials thrown away by others to sell for profit. Waste picking is very important and provide a lot social benefits especially in cities that don’t have recycling programs. There are about 40 million waste pickers around the world, with over 260,000 waste pickers in over 320 waste picker organizations, according to data from Global Alliance of Waste Pickers. Most waste pickers spend up to 12 hours a day walking around, collecting other people’s garbage and only earn less than $2 a day.

One startup is doing its part to change the world by reducing the amount of plastic waste in landfills around the world. Founded in 2016 by Jasper Middendorp, Reflow is a tech startup and social enterprise that is driven to convert plastic waste into a valuable resource and to use this recycling process to grow some of the world’s poorest, ignored and underdeveloped communities. Reflow is harnessing the power of 3D printing to create a fairer, more inclusive future. By building a vast international network for small-scale production, Reflow transforms local waste streams into a premium material to match all your creative needs. Reflow works with community of makers, recyclers and waste collectors and help prevent the production of more harmful plastic pollution. Together they ensure that the next industrial revolution is sustainable, global, and inclusive.

By building a vast international network for small-scale production, it transforms local waste streams into premium material to match all your creative needs. The Amsterdam-based Reflow currently has offices in Netherlands, India and Tanzania. It launched in Dar es Salaam and plans to expand to other cities. Around the world, around 40 million waste pickers currently earn less than $2 a day for their work. In Tanzania, Reflow works team of local engineers, scientists and makers. It’s helping waste pickers earn more money by turning plastic waste into a more valuable product: 3-D printing filament, the plastic thread-like material that 3-D printers use instead of ink. Recycling plastic bottles into filament helps waste pickers increase their incomes by as much as 20 times.

“This is born out of my experience working with social enterprises in Nairobi, Kenya–just seeing waste collectors, how they live, what they have to do for the plastic, and how they struggle to support their families,” says Jasper Middendorp, founder of Reflow, the Amsterdam-based startup making the new recycled filament. “It started from seeing what are the ways we could help waste collectors improve their lives, and what are the high value products we could make.”

Reflow filament is made from recycled PET plastic (93%) gathered in Tanzania. PET is a strong and light-weight material suitable for all 3D FDM printers that are capable of printing in a range of 225°C – 235°C (435°F-455°F) although a heated bed is recommended.

Impacts and Giving Back

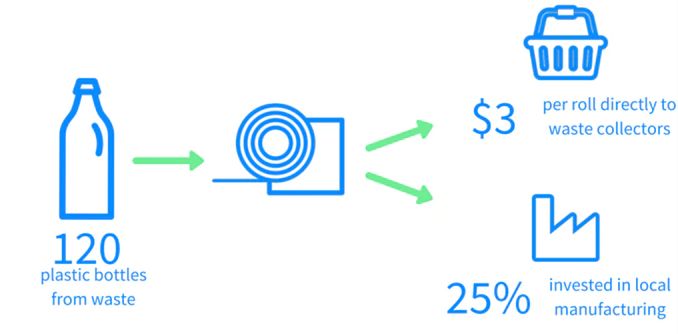

Sustainability is only part of Reflow’s story. Their vision is to improve the lives and opportunities of communities in developing regions worldwide. Reflow is making big impact in Tanzania. First, for every roll of filament, $3 directly benefits local waste collectors. Creating an alternative income stream is even more urgent now as the value of gathered plastic waste is plummeting. At least 50 million people worldwide earn less than a $1.50 a day collecting waste in abhorrent working conditions, struggling to avoid the poverty trap. We can increase the value of gathered PET plastic by as much as 20 times, allowing us to stabilise waste collector incomes and pay them the wages they deserve.

Second, to build a truly better world, a fundamental shift is needed in how local economies in these countries operate: from import dependance to self-sufficient production. Reflow believes technology paired with localized and decentralized production will play an critical role in this change. That’s why they invest 25% of their profits into exciting local manufacturing initiatives, from small scale CNC milling equipment to 3D printers made from e-waste. Reflow is not only changing the world, it is also providing jobs to the local community in Tanzania and putting smiles on people’s faces.

You can read more about Reflow on Kickstarter